Blog

Upgrade Your Spring Roll Line: Solve Mixing, Cooling & Yield Challenges with VersaTherm

If you’re already producing spring rolls, you know the challenges: holding texture through cooking, maintaining consistent yields, and hitting food safety targets without slowing down production. Our customers came to us with these exact issues — and we designed the VersaTherm Blending Cooker to solve them. Watch our spring roll video to see how it…

Smarter Production, Same Trusted Equipment: How Hanssens Catering Leveled Up with Blentech Automation

When a company runs 12 Blentech kettles for nearly two decades you know they’re serious about quality and consistency. But Hanssens Catering in Wevelgem, Belgium didn’t stop there. In 2024, this longtime Blentech customer took their food production to the next level with a full automation retrofit—adding our AutoChef® and ARTIS® platforms to their existing…

Bringing Tomato Sauce Production to Scale: How Blentech Innovates for Consistency and Quality

At the Blentech Innovation Center, we help food processors take the guesswork out of scaling up their recipes. Through rigorous testing and process optimization, we ensure that equipment upgrades lead to improved efficiency, consistency, and product quality. Our Horizontal Kettle transforms traditional sauce-making by preserving natural flavors while ensuring precision blending and sautéing, for home-cooked…

World Mithai Namkeen Convention and Expo 2024

We’re excited to introduce Blentech’s innovative solutions to the world of Indian cuisine. Our advanced cooking technology is designed to address the unique challenges of traditional dishes like curries and prepared snacks, offering a precise, efficient, and cost-effective alternative to conventional kettle cooking. Visit Dan and Jeffrey from Blentech at the World Mithai Namkeen Convention…

IFT 2024: Trends That Will Shape the Future of Food

The Blentech team is thrilled to be back exhibiting at the IFT First Trade Show taking place July 15th-17th at McCormick Place in Chicago. Stop by to visit us at booth #714 and hear about our newest technologies, talk about your current and upcoming projects, and see a demo of our ARTIS automation in action.

See You Next Week at IFT First!

We are pleased to announce that next week, Blentech will be showcasing at IFT First 2024, the leading trade show for the food innovation happening from July 15-17, 2024, at the McCormick Center in Chicago, Illinois. At IFT First 2024, Blentech will present our newest line of cost-effective machinery and advanced batch control automation software:…

See You Next Month at IFT First!

We are excited to announce that in July, Blentech will be exhibiting at IFT First 2024, a premier event for the food and beverage industry. Scheduled for July 14-17, 2024, at the McCormick Center in Chicago, Illinois, this event is a crucial platform for unveiling the latest advancements in the food industry. At IFT First…

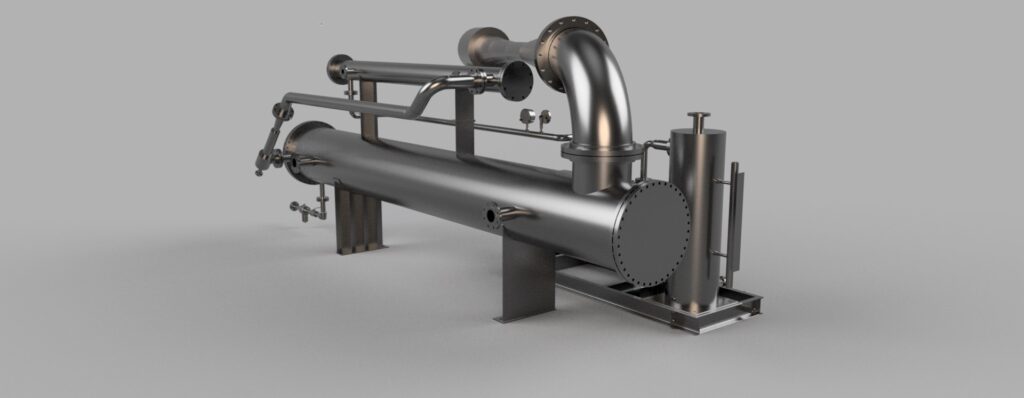

Understanding Vacuum Cooling Technology for High-Value Food Slurries

We’re sorry, but your account does not currently have access to this content.

To gain access, please follow this link to our login page. Thank you.

Our Presence at FOOMA Japan 2024

We are excited to announce that our representative ITOCHU MACHINE-TECHNOS CORPORATION exhibited at FOOMA Japan 2024, held from June 4th to 7th at Tokyo Big Sight in Tokyo. This premier event is a key platform for showcasing advancements in food machinery and technology. With over 1,000 exhibitors and more than 100,000 visitors, FOOMA Japan is…

Come Visit Blentech at Expo Pack Mexico!

Blentech is thrilled to be part of Expo Pack Mexico, currently underway in Mexico City! Visit us at our partner FoodPak’s booth #1730 to hear about our pre-engineered machinery and batch control automation software, ARTIS. Our machinery is designed to boost efficiency, reduce costs, and support sustainable practices in the food and beverage industry. Blentech…

![Close-up of [type of sauce, e.g., rich tomato sauce] made using a Blentech Horizontal Kettle.](https://blentech.com/wp-content/uploads/Tomato-Sauce-Cover-1024x576.jpg)