Blentech Blog

Gain information on news and events that are taking place with Blentech.

Pick the Right Agitator — Get the Right Food

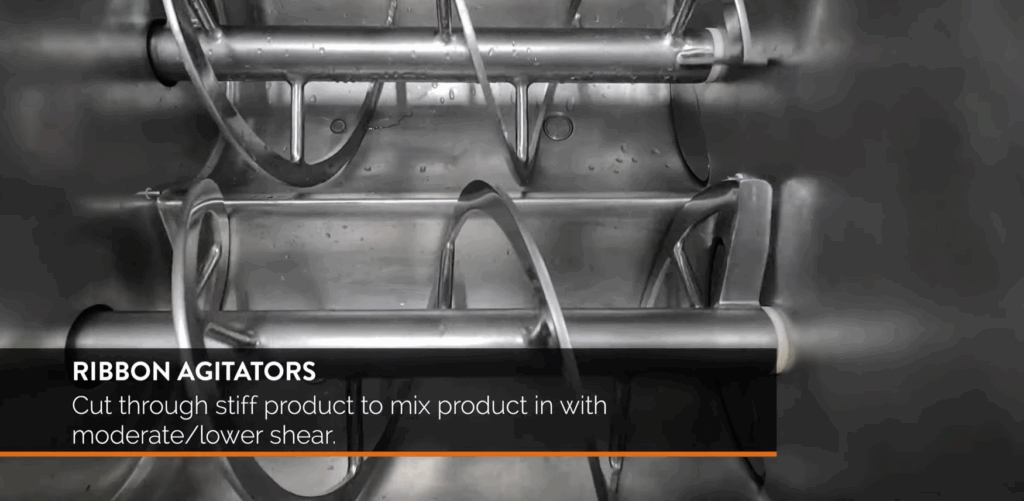

Choosing the right agitator is one of the most important decisions in food processing. In our latest video, Blentech showcases three key agitator types — ribbon, paddle, and solid flight — and demonstrates how each performs inside the Blentech Dual Mixer. Ribbon agitators deliver gentle, uniform blending ideal for delicate foods like sauerkraut and dry mixes. Paddle agitators provide the folding and smearing action critical for protein extraction and achieving the perfect texture. Solid flight agitators, on the other hand, deliver high-shear mixing for viscous, heavy, or high-fat emulsions that require intense mechanical action.

Premium Pet Food Production: Nutrition Without Compromise

Today’s pet parents expect the same care and quality in their pets’ food as they do in their own. Premium pet food producers are stepping up with fresh, nutritious, and innovative formulations — and Blentech is proud to help them scale with confidence. Whether you’re refining your first recipe or automating a full production line,…

All sizzle, no steak? Not with theVersaWok.

The Blentech VersaWok delivers high-temperature performance for authentic stir-fry, sauté, and browning applications. With its thermal oil jacket for precise temperature control, it’s engineered for consistency, speed, and chef-quality results at scale. Our new video highlights what makes the VersaWok a plant favorite — automation, repeatable performance, and perfect caramelization every time. Engineered for Extreme…

Blentech Joins UC Davis AIFS Symposium to Advance Responsible AI in Food Processing

Blentech participated in the UC Davis AI Institute for Food Systems (AIFS) Symposium to help shape the future of AI in food manufacturing.

Perfect Dumpling Fillings, Every Batch: How Blentech Solves Production Challenges

For food manufacturers, the secret to a great dumpling lies in its filling. Customers expect the same bite and flavor every time—but scaling that quality introduces real challenges. Over-mixing can turn vegetables and meat into paste, while inconsistent cooking or cooling risks both safety and yield. Blentech equipment is engineered to solve these problems directly….

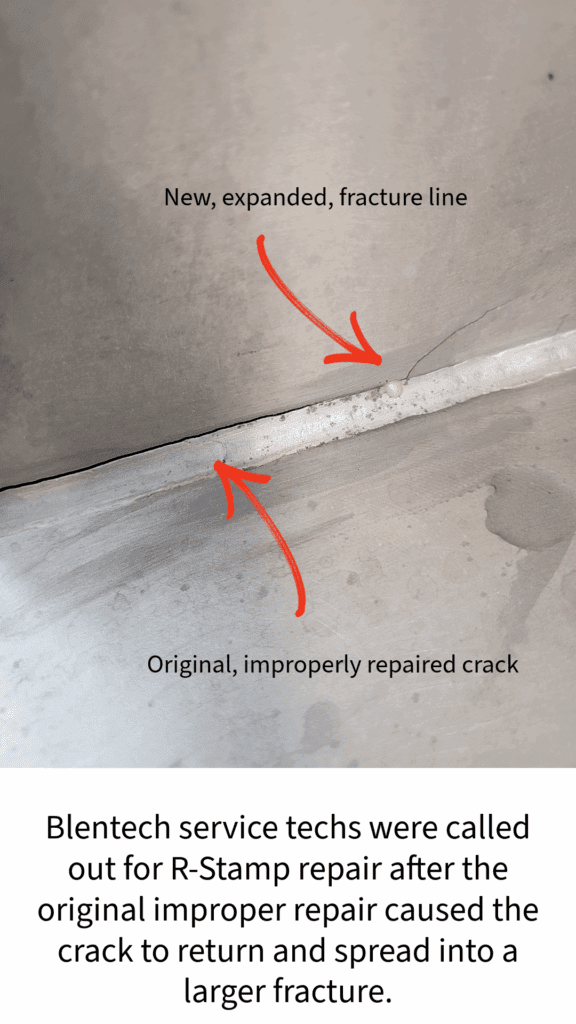

Cheaper Today, Costly Tomorrow: Why R-Stamp Repairs Protect Your Cooker’s Lifespan

Even the most durable thermal processing cookers eventually face wear. Constant heating and cooling cycles create thermal stress that can crack a steel jacket. When that happens, downtime costs start to add up quickly. When your line is down, the clock is ticking. Calling in a local welder feels like the fastest fix—but the wrong…

Keep It Clean: Maintaining Your Blentech Steam (and Cooling) Injectors

Blentech’s interchangeable injectors are designed for both direct steam heating and liquid or gas-based cooling, making them a versatile part of your thermal processing system. Whether you’re cooking sauces or chilling meats for forming, regular injector cleaning is critical for consistent performance and system safety. Here’s how to clean them the right way: Pro Tips…

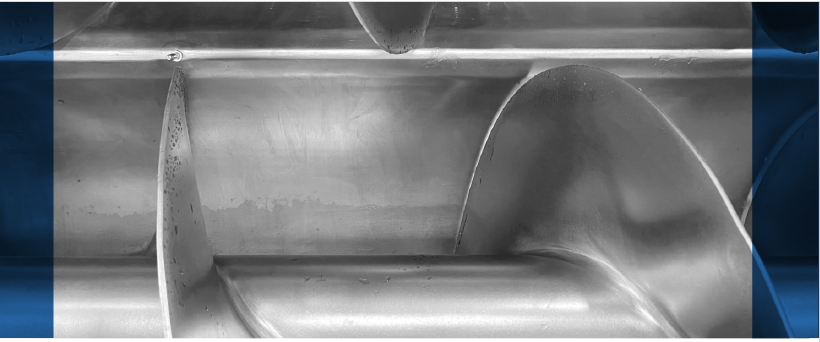

Sanitary Finish: Your First Line of Defense Against Contamination

In food manufacturing, appearances deceive. A machine may look spotless, but shiny isn’t smooth—and only smooth is sanitary. Rough welds and surface crevices trap residue and microbes, putting food safety, compliance, and uptime at risk. That’s why sanitary finish isn’t a spec—it’s a strategy. What Makes a Surface Truly “Sanitary”? Food safety authorities like the…

Configure-to-Order: Custom Without the Wait

In food manufacturing, speed and flexibility matter. Starting every project from scratch adds risk and delay, but “off-the-shelf” systems rarely fit. That’s why Blentech uses a Configure-to-Order (CTO) process—a smarter way to get equipment tailored to your needs, without reinventing the wheel. How It Works We start with a library of proven, engineered modules—cookers, conveyors,…

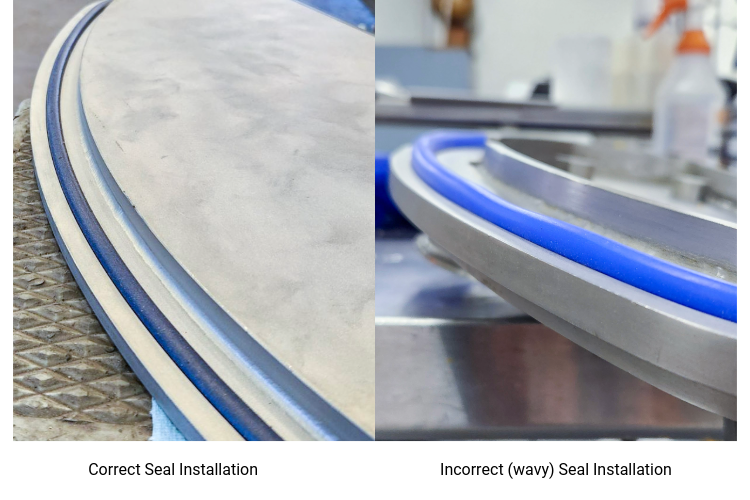

Door Seal Replacement – A Simple Step for Long-Term Performance

At Blentech, we design equipment that’s built to last—but like any high-performance system, a few wear parts need periodic replacement to keep things running smoothly. One of the most common? Door gaskets. Found on equipment covers and discharge door assemblies, these FDA-approved seals play a critical role in maintaining sanitation, ensuring leak-free operation, and protecting…

Let’s Build Your Ideal Kettle System

Ready to design a kettle that delivers the performance and flexibility your process demands? Schedule a free consultation to discuss your application with a Blentech process expert.