Systems That Work the Way You Do

It’s not just about single machines — it’s how the whole system works. We integrate cooking, mixing, handling, and automation into one proven solution that keeps your production running smoothly.

Why Blentech Systems Work for You

REDUCE LABOR

Integrated loading, unloading, and automation.

IMPROVE YIELDS

Consistent cooking and mixing for less waste.

CUT DOWNTIME

Easy-to-clean designs and CIP options.

SCALE PRODUCTION

Modular platforms and inline configurations.

System That Are Built to Perform

HORIZONTAL KETTLE SYSTEMS

For sauces, soups, spreads, fillings, and meat blends. Outperforms traditional designs with faster batch cycles, higher throughput, and integrated automation.

THERMAL SCREW SYSTEMS

For shredded meats, pasta, and bacon crumbles. Optimized for continuous cooking, cutting labor and waste with throughput up to 20,000 lbs/hr.

DUAL RICE COOKING SYSTEMS

For rice, grains, and seasoned blends. Engineered with optimized agitation and steam control to lock in quality and reduce overcooking.

CHEEZTHERM SYSTEMS

For processed and vegan cheese. USDA-compliant design with high-shear loops for stable emulsions and surge-controlled forming.

LIQUID NITROGEN CHILL AUGERS

For bacon bits and ground proteins. Zoned flow control and intermeshing agitation chill evenly and efficiently, reducing cryogen use.

VACUUM COOLING & COOKING

For moisture-sensitive products and starches. Rapidly cools products to 40°F with no carryover, ensuring final moisture control to spec.

Clarity in Planning. Discipline in Execution.

From kickoff to start-up, our project managers and engineers own the details with clear schedules, single-point coordination, rigorous design reviews, FAT/SAT, commissioning and training—so your system lands on time, passes audits, and runs right on day one.

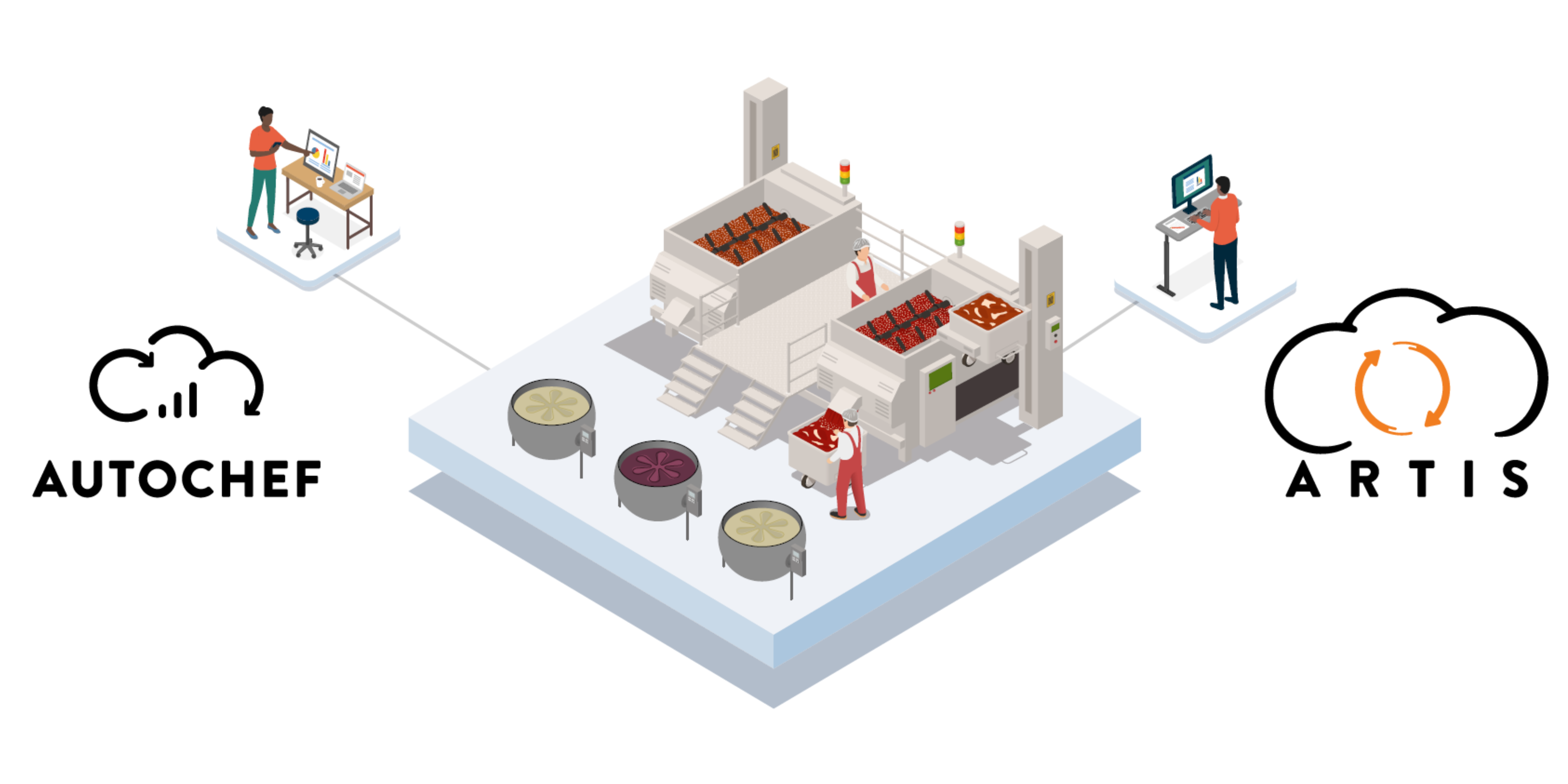

AUTOMATION READY FROM DAY ONE

Pair your horizontal system with AutoChef, Blentech’s automation platform, to control speed, direction, and run time for every step. This ensures repeatable results across shifts and makes scaling easier, from five batches to five thousand.

Add ARTIS for advanced data reporting, QA tracking, and compliance documentation to support audits, continuous improvement, and customer trust.

Designed, Tested, Proven

All of our systems are validated at the Blentech Innovation Center. Our team supports you with full systems engineering, on-site trials, and performance validation.