Maintenance

Cheaper Today, Costly Tomorrow: Why R-Stamp Repairs Protect Your Cooker’s Lifespan

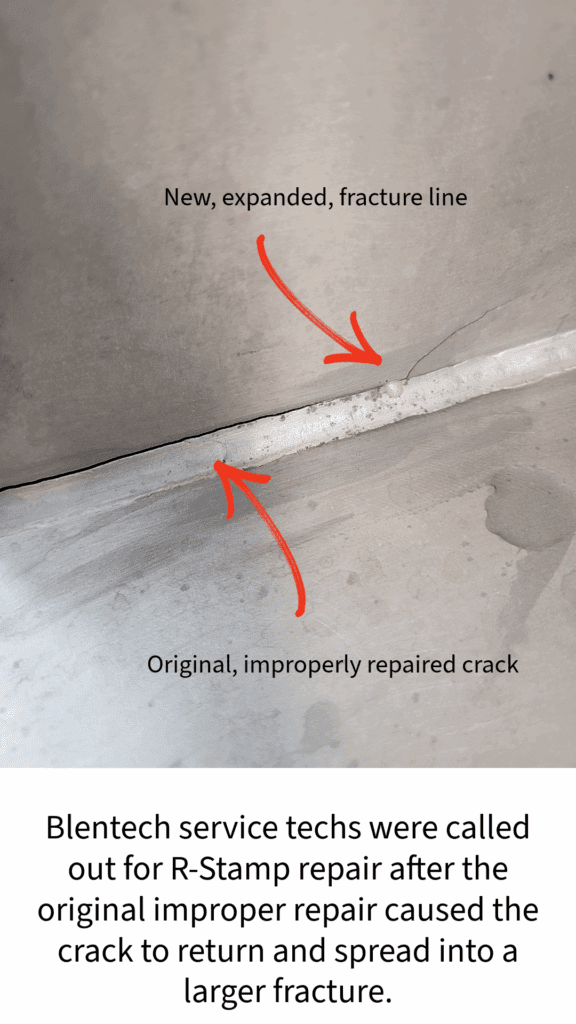

Even the most durable thermal processing cookers eventually face wear. Constant heating and cooling cycles create thermal stress that can crack a steel jacket. When that happens, downtime costs start to add up quickly. When your line is down, the clock is ticking. Calling in a local welder feels like the fastest fix—but the wrong…

Read MoreKeep It Clean: Maintaining Your Blentech Steam (and Cooling) Injectors

Blentech’s interchangeable injectors are designed for both direct steam heating and liquid or gas-based cooling, making them a versatile part of your thermal processing system. Whether you’re cooking sauces or chilling meats for forming, regular injector cleaning is critical for consistent performance and system safety. Here’s how to clean them the right way: Pro Tips…

Read MoreDoor Seal Replacement – A Simple Step for Long-Term Performance

At Blentech, we design equipment that’s built to last—but like any high-performance system, a few wear parts need periodic replacement to keep things running smoothly. One of the most common? Door gaskets. Found on equipment covers and discharge door assemblies, these FDA-approved seals play a critical role in maintaining sanitation, ensuring leak-free operation, and protecting…

Read MoreScraper Tips and Tricks: Get the Most Out of Your Blentech System

Here’s how to optimize your scrapers for the best performance. Scrapers do more than sweep the bowl—they prevent burn-on, improve mixing, and help maintain consistent texture and flavor, especially in thick or delicate blends. By keeping heated surfaces clean, they reduce waste, support even heating, and protect product quality. Regular inspection and timely replacement are…

Read MoreDielectric Grease & Sensor Reliability in Washdown Environments

A simple maintenance step to protect sensors, reduce downtime, and improve reliability in washdown food production environments. At Blentech, we engineer our systems to perform in the most demanding food production environments, including areas with high-pressure washdowns. Even though our sensor cabling is wash-down rated, one simple practice can go a long way in protecting…

Read More