Food For Thought – Part 1

Over the Thanksgiving holiday, I was thinking about the phrase “Food For Thought”. That phrase really has so many meanings depending on each of our different perspectives. In today’s first post in a four-part series, I’d like to discuss some of the current challenges and changes to come in the food processing industry.

Ready-to-eat meal (RTE) manufacturers face a challenge of tight profit margins on frozen entrees. COVID-19 has caused a surge in demand for frozen foods across all varieties, from ethnic Indian RTE meals to frozen pizzas. Data suggests frozen food sales are holding 30-35% increase in sales from similar periods in 2019 [1]. This surge in demand is caused in part by heightened consumer demand for alternative options to dining out. In response, ready to eat meal manufacturers are maximizing their throughputs and making capital investments to scale their operations.

The principles and unit operations of making RTE meals has not changed drastically over the past several decades. In fact, frozen RTE meals are meant to resemble the same flavors, texture, consistency, and mouthfeel of dishes consumers would prepare at home. Sensory testing of RTE meals proves the appearance on store shelves plays an important role in the purchase behavior of consumers. This means that regardless of the taste or flavor of a meal, if a meal does not look appealing on store shelves, it will not be purchased. Similarly, how the meal appears after it is thawed/cooked also plays an important role in the likelihood that the consumer will become a repeat customer.

Manufacturers who pride themselves on producing high quality RTE dishes strive to mimic stove-top unit operations at a large scale. For example, producers of Indian RTE dishes understand the importance of sautéing onions and slow cooking of dishes to allow for full flavor development. They try to keep the process as similar as possible to stove top operations, and do not try to cut corners. This can become challenging as manufacturers are forced to rapidly increase production while maintaining quality and profit margin. Oftentimes, manufacturers have to sacrifice one for the other. As the production scale grows, equipment becomes less energy efficient and the food quality can take a big hit if not properly scaled. Blentech helps manufacturers solve the problems of quality at scale while maintaining, or even improving profitability on a per pound final product basis. Nearly every week, our Blentech Innovation Center is working with our customers to provide solutions to help solve exactly these types of problems.

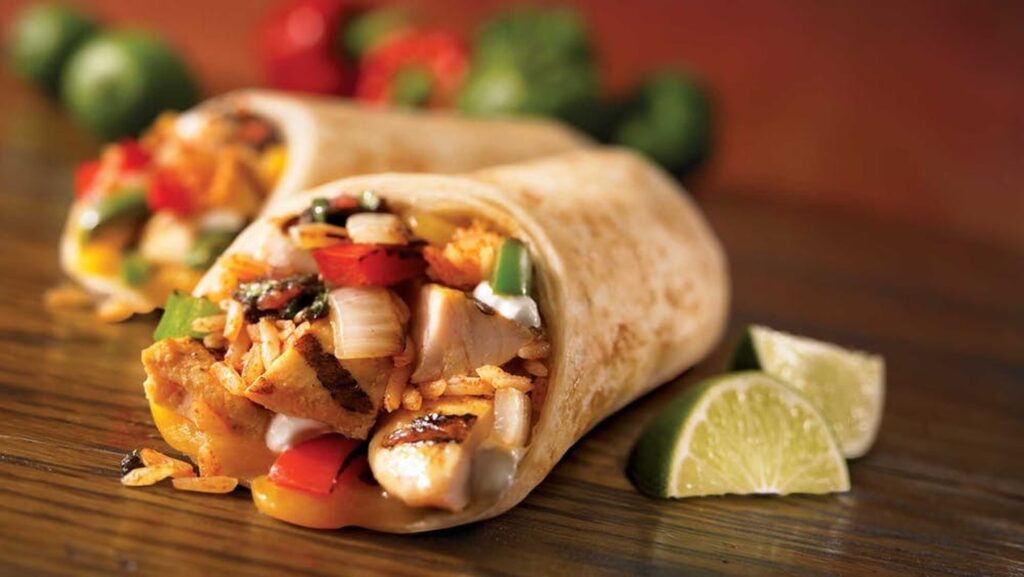

Take for example burrito manufacturing. Small scale food production of burrito fillings might utilize tilt skillets for cooking the various parts of a burrito filling– beans, eggs, meats, and sauce. Typically this product will be handled very gently with great care to not damage the particle integrity of the beans and eggs. After cooking, the filling is likely chilled in a blast freezer to below 40 degrees Fahrenheit to keep it within the safe zone and prevent pathogenic bacteria growth. At this scale, this product will visually be appealing because of the handmade nature and will likely have great flavor because it is made in small batches. Customers who purchase this product likely are repeat customers, and this business is slowly growing at a profitable and consistent growth rate as it continues to acquire new customers and grow its product line.

Say this same business saw a huge jump in demand due to COVID-19, as has happened to several RTE meal manufacturers. The manufacturer is forced to either scale production with more tilt skillets or choose large scale batch manufacturing cookers. If the manufacturer chooses to scale with more tilt skillets, this presents the challenge of increased labor costs to operate the tilt skillets and a logistical nightmare to prepare, stage, and load the ingredients for each small batch. Furthermore, the product quality may become inconsistent due to the number of batches being cooked. If the manufacturer chooses instead to purchase a large scale batch cooker, this will be more efficient, but there may be a quality issue where the product does not have the same sensory attributes such as look and taste compared to the smaller batch. Similarly the product will have to be cooled, and new options must be evaluated such as cryogenic cooling or vacuum cooling. Blast chilling poses a significant challenge due to the footprint and energy efficiency and is typically not considered at larger scales.

Product scale up can be a challenging, but rewarding process for manufacturers. If manufacturers are able to strike the right cord and grow the bottom line based on economies of scale, while keeping the same quality, or even improving it, it is considered a huge win for customers. At Blentech we’ve worked with several customers who have worked through these challenges. Check out what Blentech customer Sweet Earth had to say about this process.

At the core, we believe the north star is designing equipment that makes delicious, good tasting food customers love. Blentech has been trusted with scaling up some of the world’s most relished food products. Those of which have been made for generations. While COVID-19 has been a challenge for the world as a whole, it has provided RTE meal manufacturers with an opportunity to grow and gain market share unlike ever before. The food and beverage industry is used to seeing a steady 2-3% year over year growth corresponding to the growth in population. When scaling up to meet increasing demands, manufacturers must remember to find the right partner.

Sales Engineer

Contact us today to discuss your RTE and scale up needs – or schedule time in our Innovation Center to test your product.